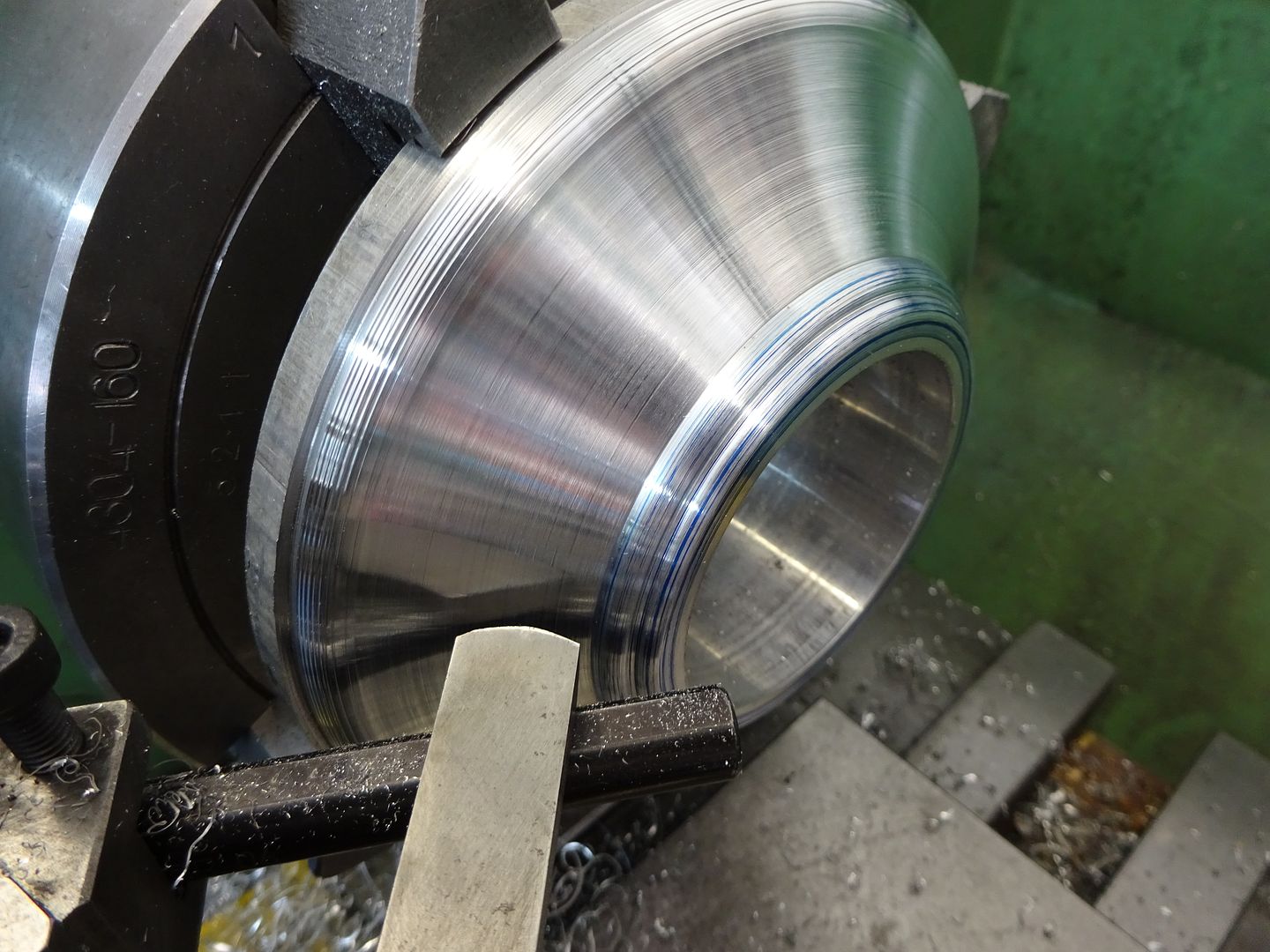

Many years ago, beyond memory, at Tech we were given a mathematical proof that a crowned pulley caused the belt to run on the top of the crown.

There have been millions of pulleys confirming this.

Kempes Engineers Year book, 1982 in section E9/3, referring to flat belts, calls for pulleys to be cambered, with either a smooth curve or two symmetrical smooth curves with a central flat portion not exceeding half the width of the belt. It also says that flat tapers should not be used since they introduce stresses into the belt, and decreases contact between belt and pulley.

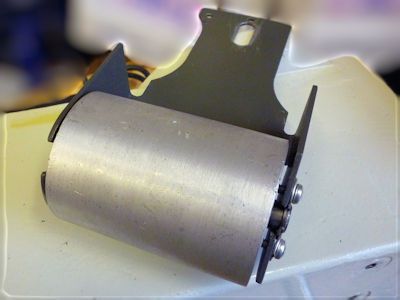

Like Jason, I would probably use two very slight tapers with a central flat portion

So the transition from the slight taper needs to be blended into the central flat.

It says "The effectiveness of the camber depends on the ratio of camber to pulley diameter, and is practically independent of belt width. It is affected by length of drive and by pulley diameter itself, but not to any significant extent".

It also says that "If the pulleys are very different in size, it is good practice to leave the smaller pulley flat and provide all the necessary camber on the larger pulley"

All the A7 fan pulleys that I have seen have been crowned

HTH

Howard

Mick B1.