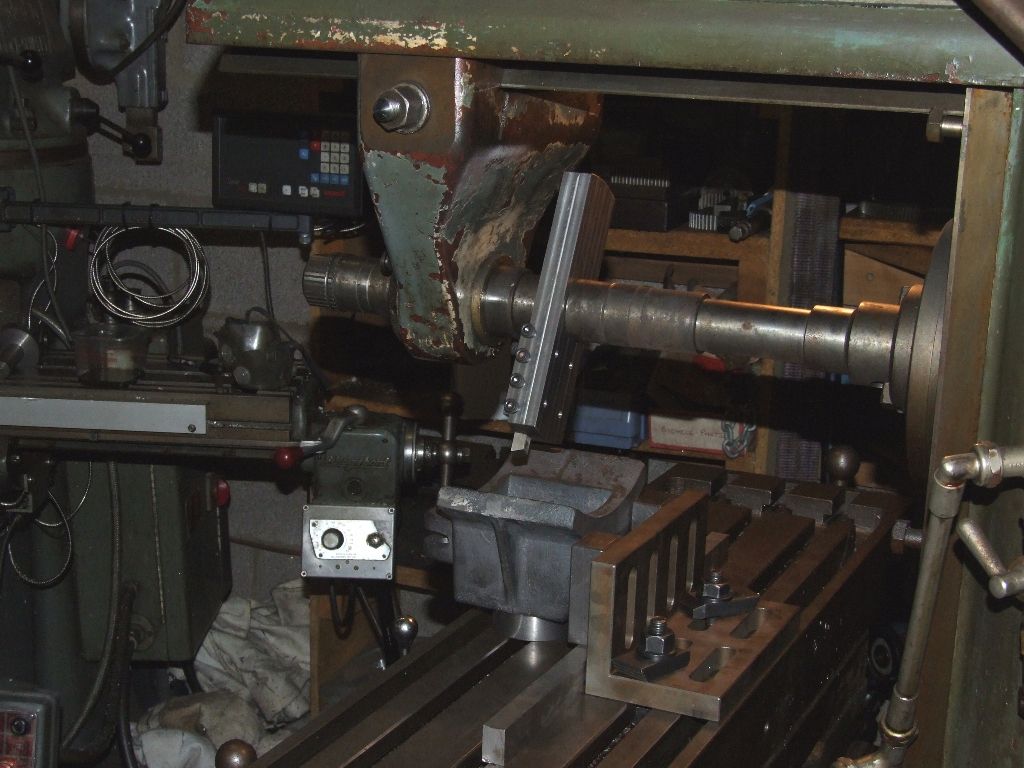

Unlike most folk here I leave the swivel base on. I like the ability to clock the vice true when needed although my usual method of pulling it back hard against the studs before tightening in stages usually gets to around a thou or two in 4". My vice slots aren't that accurate relative to the jaws but tweaking the swivel easily took care of that. But I have a Bridgeport with plenty of vertical room.

For a non swivel vice I'd seriously consider flipping it over, clamping to a bar accurately aligned with the table and machining the slot sides true to each other and to the jaws. Make a T shape clamping "washer" with the lower part of the stem fitting nicely but not too tightly in the table slots and the upper part a similar fit in your re-worked vice slots. The pull back when tightening technique should then get you alignment accuracies rather better than mine. Not quite up to a well fitted key but close and far easier to shift.

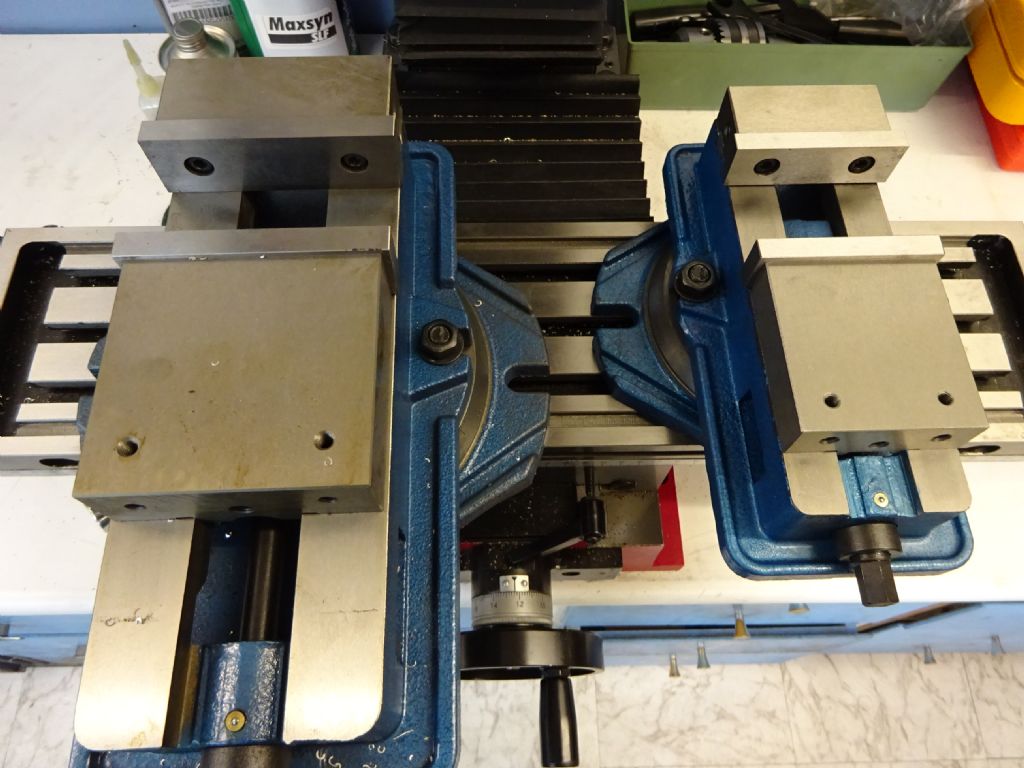

I like my pair of the Vertex VJ-400 110 mm x 180 mm vices **LINK** . Basically a mechanical screw version of a lower end hydraulic vice they can be set to three different maximum openings. Normal vices are pretty much square capacity so a 110 mm / 4" jaw width vice opens to around 110 mm / 4". The VJ-400 goes out to 180 mm / 7" if need be so combining the lighter weight of a 4" vice with the ultimate capacity of a 7" one. Obviously it hasn't got the grip of a true 7" vice but I've always found it enough when needed. Generally I find it gets used pretty much as a 5" nominal vice. Relatively expensive now and lacks the fancy Kurt style angle lock anti jaw lift device but I find it a good performer.

Hafta say I'm more than a little skeptical about the practical behaviour of all the fancy automatic anti-jaw lift systems. I figure the benefit is ore due to being on a well made, or well fettled, vice.

As far as weight is concerned didn't Chick, the One-Lok people, use an alloy base at one time. I've long been tempted to try my hand at a home brew version.

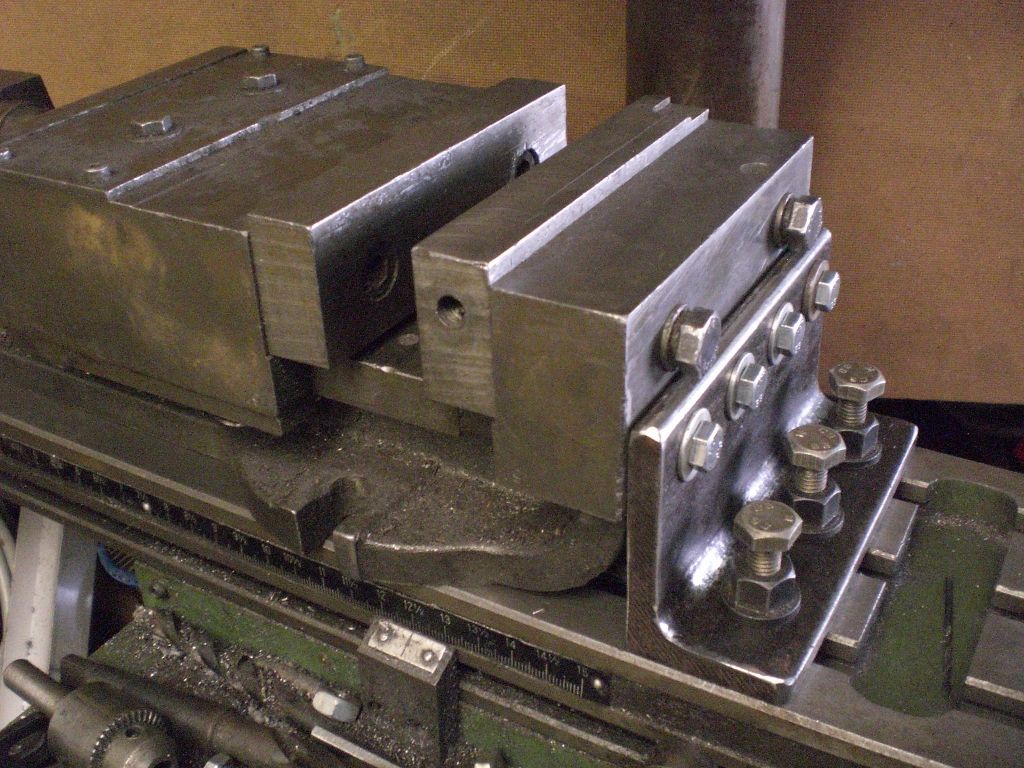

If you want something bigger at, possibly, a more affordable price maybe the adjustable planer vice published in Popular Mechanics **LINK** would be a useful source of inspiration for a home build. Looks quite amenable to bolt up from lumps construction. Getting the working faces of the jaws dead square to the base looks to be the only part needing extra care.

Clive

Clive Foster.