Posted by Steviegtr on 07/05/2020 01:12:39:

My take on this, is that a gib strip runs on usually cast iron. we all know from metallurgy that for 2 metal rubbing together that one would be made from a hard metal substance & one from a soft substance. Hence my reasoning of cast iron to Phosphor bronze. Especially as the bronze can be oilite. It will stay lubricated for longer than any other metal. Or is it too soft & would not pack correctly. Silly old duffer will have an answer in the morning I am sure that will blow my theory away.

Steve.

Theory safe, but I can fill in some of the whys and wherefores! Not due to my natural genius, but I do have a collection of books!

- D.A.Low's "Applied Mechanics" (Longmans, London 1947) has much of interest to say about Mr Beauchamp Tower's researches. Stephenson, Brunel and Whitworth are remembered despite their efforts being mostly obsolete. Poor old Tower is mostly forgotten, but he's the guy who sorted out modern lubrication, a far from simple subject. Unfortunately Low doesn't explain why two different metals should be used in a bearing.

- "Engineering Hand-drawing and Scale-Drawing" Jackson & Bentley, Leeds undated is full of drawing exercises covering common pre-war engineering objects, together with a short description of design features. For a cast bearing, it says 'BB is a Brass "Bush" or "Lining". The use of this liner or bush tends to reduce the "wear" of the "journal" by making it "run" more easily and smoothly than if it were rubbing on the cast-iron. (The bearing can also be renewed cheaply and easily by putting in a new bush)"

- "Introduction to Machine Design, Jefferson & Brooking, Ronald Press, New York 1951" gets into the nitty gritty:

- Sufficiently strong to bear the load

- Readily machinable and able to take a high degree of polish

- Have low frictional resistance

- Able to function within the temperature range of the machine

- do not readily gall, ie seize

Of these, not galling, generally means a bearing must be made of two different metals. The book says the main exceptions are: cast-iron may be run against cast-iron, and mild-steel may be run against hardened steel. Not any pair of different metals work without galling, examples of OK pairs given are:

- Babbitt metal, good for heavy pressure and shock loads because it's plastic. Failed bearings don't score.

- Brass, takes more pressure than Babbitt, but not good for shock loads. Cheaper than better bearing metals, main advantage – easily replaced

- Bronze, very high pressure

- Copper-Lead, good for high-pressure and high-temperature in engines. Failed bearings don't score.

- Silver, and Silver Cadmium, high load, high speed, precision machines

- Powdered metals (Oilite etc), low load, low speed, low maintenance (ie machine is done when they wear out)

- Plastics, water lubricated, high-pressure, dredging machines

- Rubber, water lubricated underwater bearings

- Cast-iron with hardened steel, slow speed light load machines, cheap

- Steel, sliding bearings, especially ball and roller bearings. (polished to better than 0.0001" with high hardeness and toughness.)

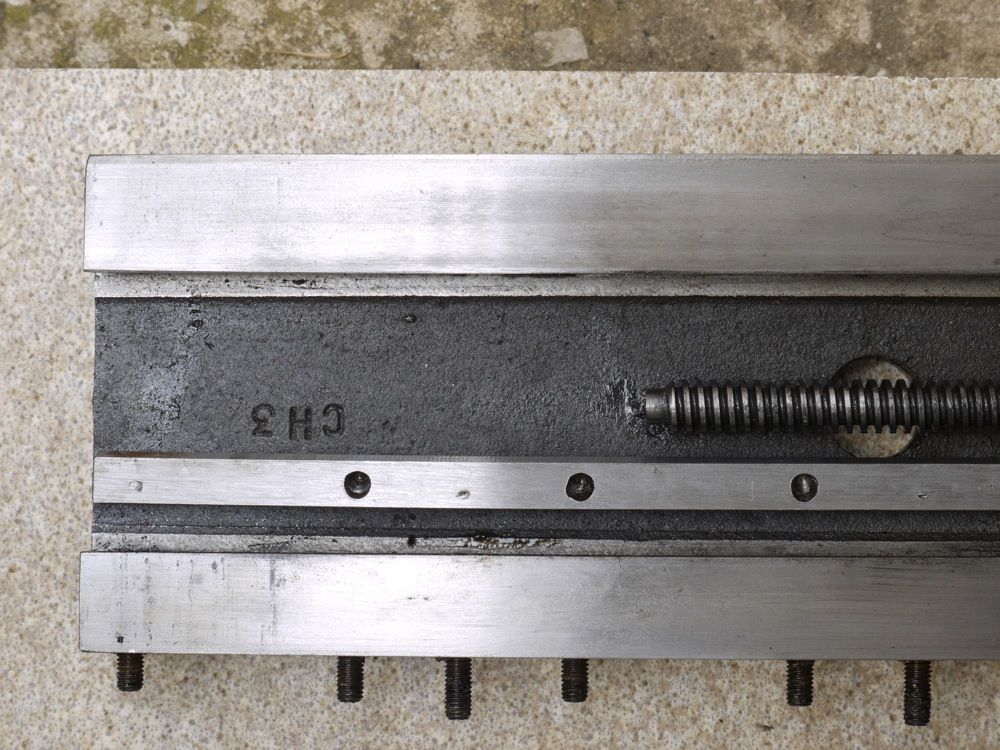

So Phosphor Bronze is OTT for lathe gibs, cast-iron more likely, maybe mild-steel for cheapness, or brass because it can be polished. Big machine slides might be different, but gibs don't generally have to cope with high-pressure, high-loads, or high-speed. Be fun to fit silver gibs, massive boasting rights, and it would deter vampires!

Dave

Dave

Steven Kane.