Posted by andrew lyner on 19/04/2020 11:51:51:…

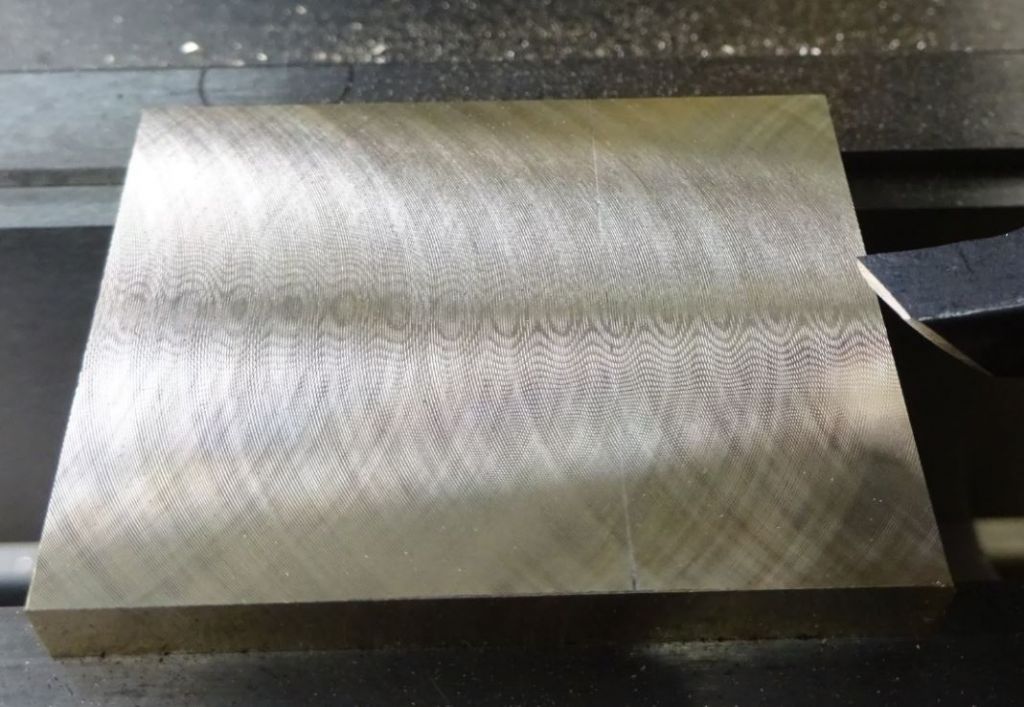

Can I expect to improve on the 0.25 mm I have measured.

Reviews of the mill are not too enthusiastic about the tilt adjustment on a lightweight lathe.

Yes to both statements!

The tilt adjustment on this family of milling machines is pretty basic. On my bigger version of the same type of mill it's easy to get within spitting distance of a good tram, but downright tricky to catch and hold it on target.

Tightening mine up often causes the tram to shift slightly at the last moment. A typical sequence is 'not quite close enough', 'bit better', and 'much better'. This is followed by disaster on nipping up, with the head nudging back to 'not really good enough' and an outbreak of bad language.

First time I had to reset tram after moving the head to take an angle cut it took only 3 attempts to restore sanity. A false dawn, the second tram took far more effort – I lost count. I'm not aware there's a particular trick to tramming these machines, the problem is just making absolutely sure nothing moves on the final tighten. Patience.

Tramming is such a nuisance I avoid moving the head if possible. When angled cuts are needed, I prefer to tilt the job rather than incline the milling head.

Dave

andrew lyner.