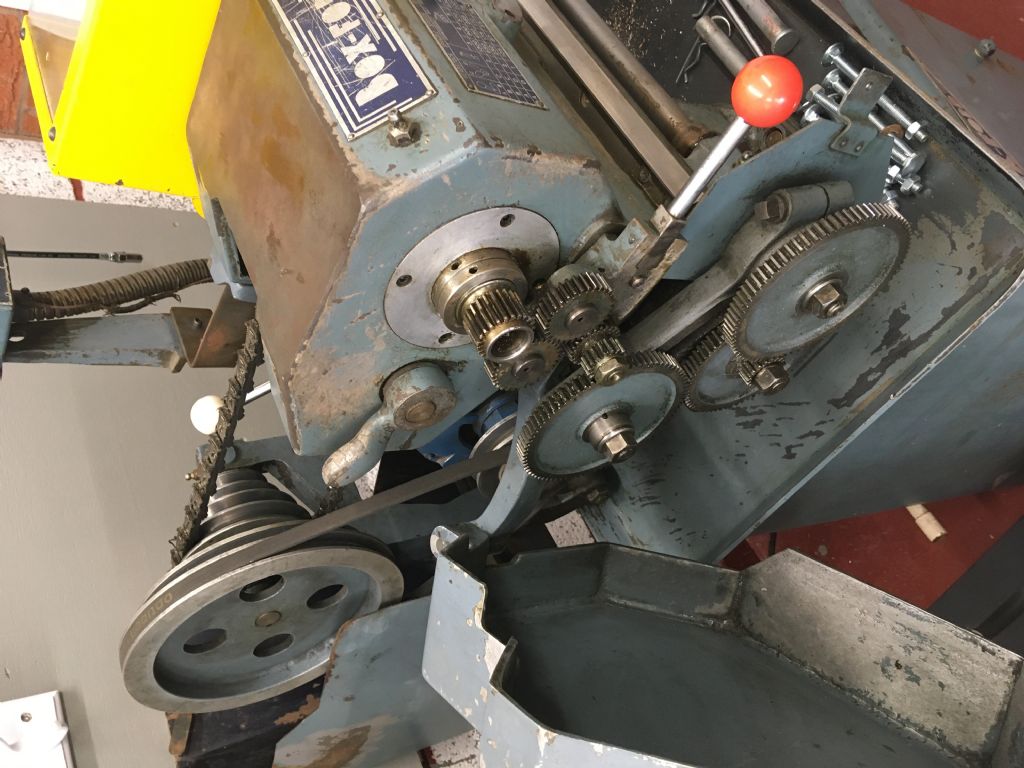

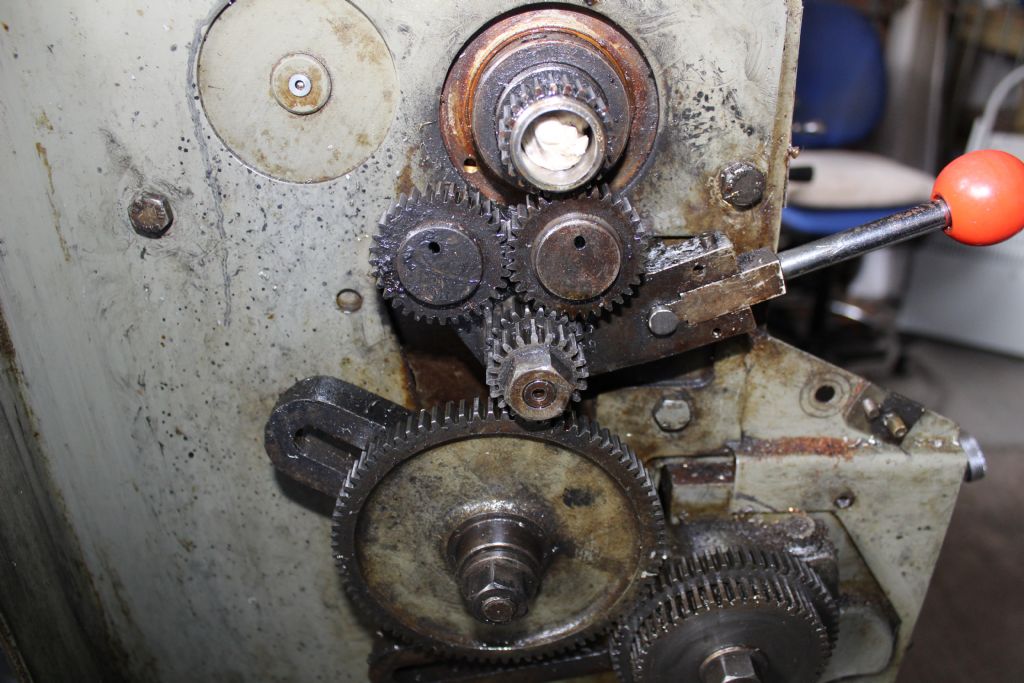

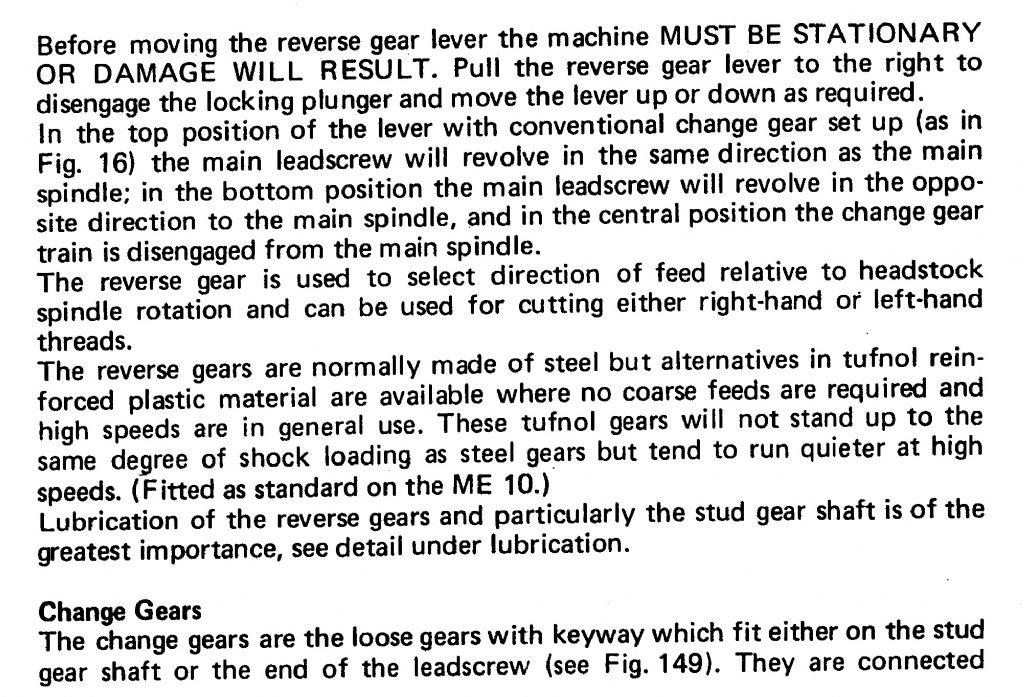

Can't add much to Martin's reply, but "locking up" sounds a trifle worrying in case of damage. Do you mean the main spindle or just the gears themselves. The red knob has three positions, each with a spring detent.

For a Boxford "C", with no power cross-feed;

1, carriage moving right to left; 2. neutral; 3. carriage moving left to right.

To reverse the main spindle, the motor must be reversed by its switch.

The change gears should be set up with small but definite free backlash between each stage, otherwise they might bind up at some point in their rotation. This backlash on the banjo gears can be adjusted by small movement of the axles which are clamped by a nut behind each gear. The mesh of the topmost gear can be adjusted by slackening the clamp bolt behind the gear on the leadscrew and swinging the whole banjo.

Put the red knob in neutral and see if you can turn the gears by hand in both directions.

Hope that helps.

Edited By Clive Brown 1 on 18/04/2020 15:55:21

Steve Jones 20.