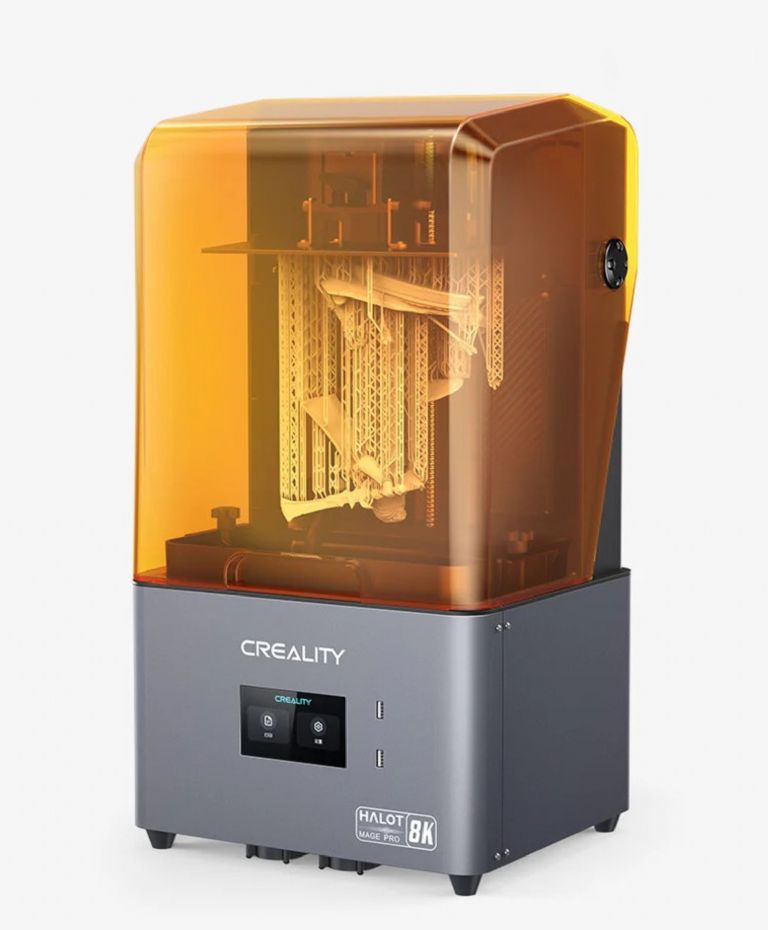

The Halot-Mage Pro is Creality’s top of the range model and physically it is considerably bigger than its predecessors at 335 x 270 x 610 mm in size and 13.3kg in weight. The machine came packaged to a high standard, inside a stout outer box with plenty of foam packing.

Design

Enjoy more Model Engineer reading in the monthly magazine.

Click here to subscribe & save.

It’s a big, good-looking machine. The most noticeable feature of the Halot-Mage Pro is that instead of having a UV shield in the form of a large lift-off lid, it has pivoting guard that lifts up to give excellent access to the machine. The ‘Mage Arch’ is a great feature as it means you don’t have to reserve an area for the lid. This means you can use it in a similar amount of space as a smaller machine.

Speed

The most notable feature of the Halot-Mage Pro is speed. It’s immediately noticeable how the build platform moves much faster when raising and lowering.

The time taken to raise and lower the build plate draws out the printing process. The Mage Pro has a larger, more powerful motor drive than most printers allowing it to move the platform faster yet without stalling. The machine is noticeably faster than the Halot One Pro even in standard mode with ordinary resins, but it also has a so-called ‘Dynax mode’ used with special ‘fast’ resins.

In Dynax mode the build plate lifts and lowers in just 1.2 seconds, this really does mean prints appear much faster. Creality’s claimed figures are 170mm/hr and 70mm/hr in the two Dynax modes, compared to typical 25 to 50mm/hr speeds of other printers. I printed exactly the same, tall, model on both the Halot One Pro, and the Halot-Mage Pro (in Dynax mode with fast resin). The calculated print times were 11 hours 20 minutes and 3 hours 35 minutes, respectively.

I found the high-speed resins give reliable results when used in Dynax mode but you must use the correct ‘high speed’ settings for these resins in the slicer. Clearly being limited to a smaller range of resins means there are fewer things you can do in the Dynax modes, but I found that there was no visible impact on print quality.

Print Volume and Resolution

One often heard criticism of resin printers is that the build plates are rather smaller than those of SLA printers. The Halot-Mage Pro has a larger, higher resolution 10.3” 8K LCD screen. This gives a build volume of 228 x 128 x 230 mm, about 9 x 5 x 9 inches. The 29.7um X/Y resolution compares to a more typical 50um resolution. This gives even better antialiasing and although printed surfaces have a visible texture, this is so fine it is more of a satin finish effect that completely disappears under paint.

Smart Pump

Larger prints use more resin. The resin vat of the Halot-Mage Pro is bigger and deeper, having a capacity of about a litre, but this does not impose a limit on the volume of an object that can be printed, as the printer has an integral ‘smart pump’. This appears to be a peristaltic pump and uses a flexible pipe to suck resin in and out of the vat. It has simple manual controls but can also be used in ‘automatic’ mode. This detects when the resin level gets low, and it automatically tops up the vat to 500ml. I used a tissue stuffed into the top of the resin bottle to keep out light and dust, but I will print a better cover. They claim it can transport a litre of resin in half an hour, but I found it operates rather faster than that.

Air purifier

The Halot-Mage Pro has an integral carbon filter, much larger than the earlier printers. It also comes with an extendable vent tube. This makes using the machine indoors more practical as the pipe can be poked out of a window. The tube diameter is about 40mm. I fitted a piece of kitchen drain pipe to the rafters of my workshop and arranged it to vent through the rear wall. I then extended it using large diameter flexible pond hose. I designed pipe clips and pipe joiners in Alibre Atom 3D, and printed them on the Halot-Mage Pro. I’m pleased to say vent pump happily sustains air flow despite the whole run being about 4m of pipe. I plan to expand it so it can be used for general fume extraction when anodising, soldering or doing light brazing. I will add a fume hood on the end of a flexible tube with an integral fan, that I can suspend from the ceiling off a hook above any process. I realise this system won’t cope with hot air, but like a cooker hood it will mostly be sucking in cool air.

Build plate release

It’s a fairly small point, but the Halot-Mage Pro has an interesting clamp arrangement for the build plate; a knob at the front operates a cam that wedges the plate securely. This makes it easy to release and replace the build plate. Combined with the flip-up lid these oldest ideas make handing complete prints more straightforward.

Software

For slicing, the printer comes with Halot Box, this is the same program as reviewed with Halot One Pro. It is effective, but has some quirks. It also comes with a year’s licence for Chitubox; this is a very advanced slicer with STL editing capabilities. I haven’t been able to explore this fully yet.

The HALOT-MAGE PRO uses Creality’s HALOT OS, which uses a relatively simple menu-driven interface operated through a good sized, clear colour LCD touch screen. Unfortunately my wifi connection is rather flaky in my workshop, and although I have been able to connect the printer to my home network, I haven’t been confident to make use of printing from my phone, PC or Creality Cloud as I’m worried about the signal dropping out. Instead I have used the print via USB drive facility, which I find simple to use.

I would like to get a better connection sorted for my workshop, and as the printer also supports RJ45 a long quality cable will be the most reliable answer. With this installed, I will be able to control or monitor jobs remotely from the Creality Cloud app or web interface. The convenience of being able to send a job from my PC and check on progress on my phone would be good on dark rainy nights when the workshop is locked up! It’s also possible to install a USB Camera for remote monitoring.

In Use

I’ve printed a number of test items on the Halot-Mage Pro, all using the ‘fast resin’. Initially I had few issues with parts being slightly warped. I thought this was due to poor support, but it turned out I forgot to select ‘high speed resin’ rather than ‘Standard resin’ in the Halot Box slicer program. After using the right setting my prints came out as expected.

One of my first prints was the set of pipe clips and joiners for the ventilation system in photo 6.

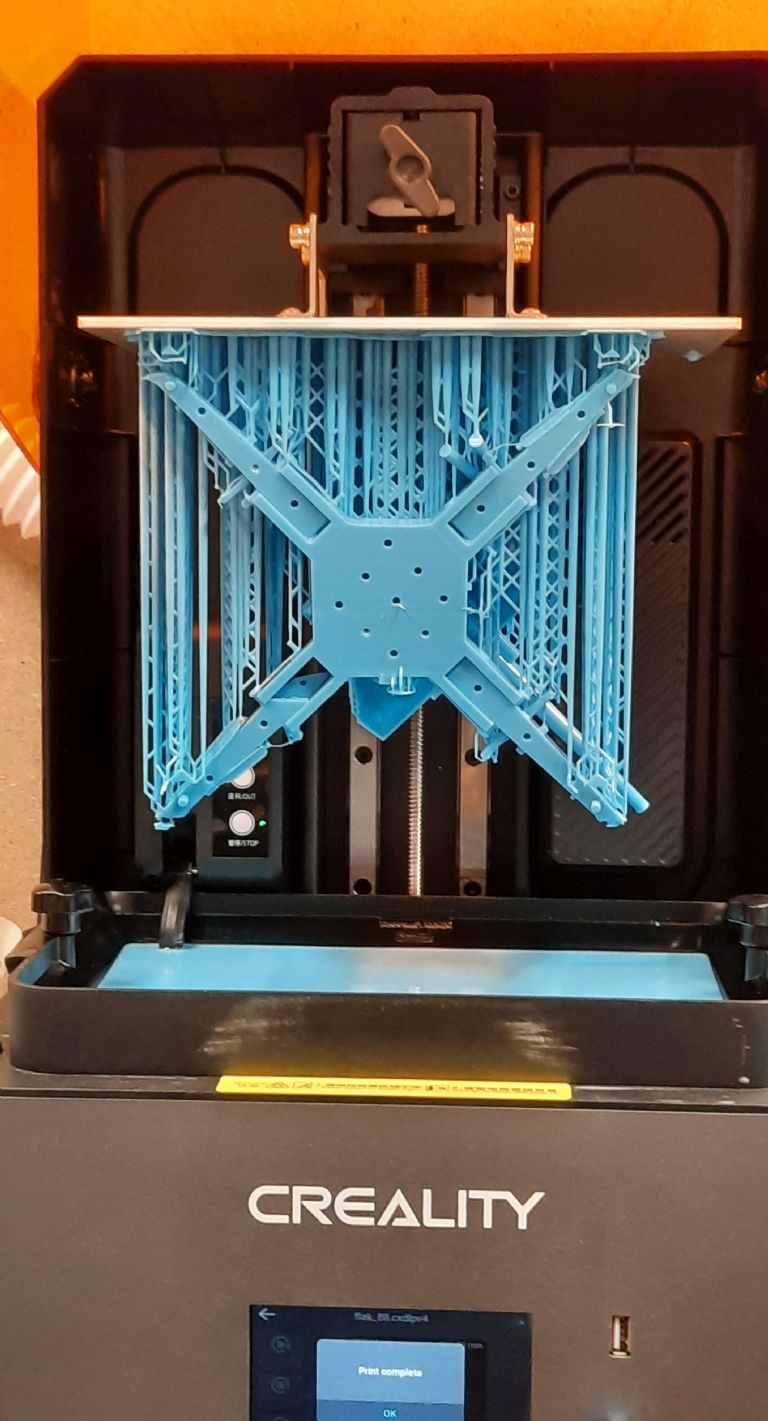

I tried printing a huge STL of a 88mm Flak 37 I downloaded from Thingiverse. This made use of almost all of the printer’s build volume. Unfortunately the ends of the legs did not print properly, this turned out to be a flaw in the model, not a fault of the printer – these parts had walls of zero thickness that didn’t print, and parts ‘joined’ to them obviously fell off. Aside from this the large and complex model printed perfectly.

To test the resolution of the printer, I designed some ‘intake meshes’ for a 1:35 Stug III model. These have 0.2mm wide bars on a 0.5mm pitch and took only 18 minutes to print in Dynax mode, a longer wash is needed to stop unset resin clogging some of the holes.

I am looking at 3D printing a 3 ½” gauge ‘Presflo’ cement wagon to two behind my electric shunter. As a trial I drew up a CAD model using the Dapol (formerly Airfix) model at 1:76 as a guide. In time I will add and improve the details, but I did a quick test print at 1:76 which turned out very well.

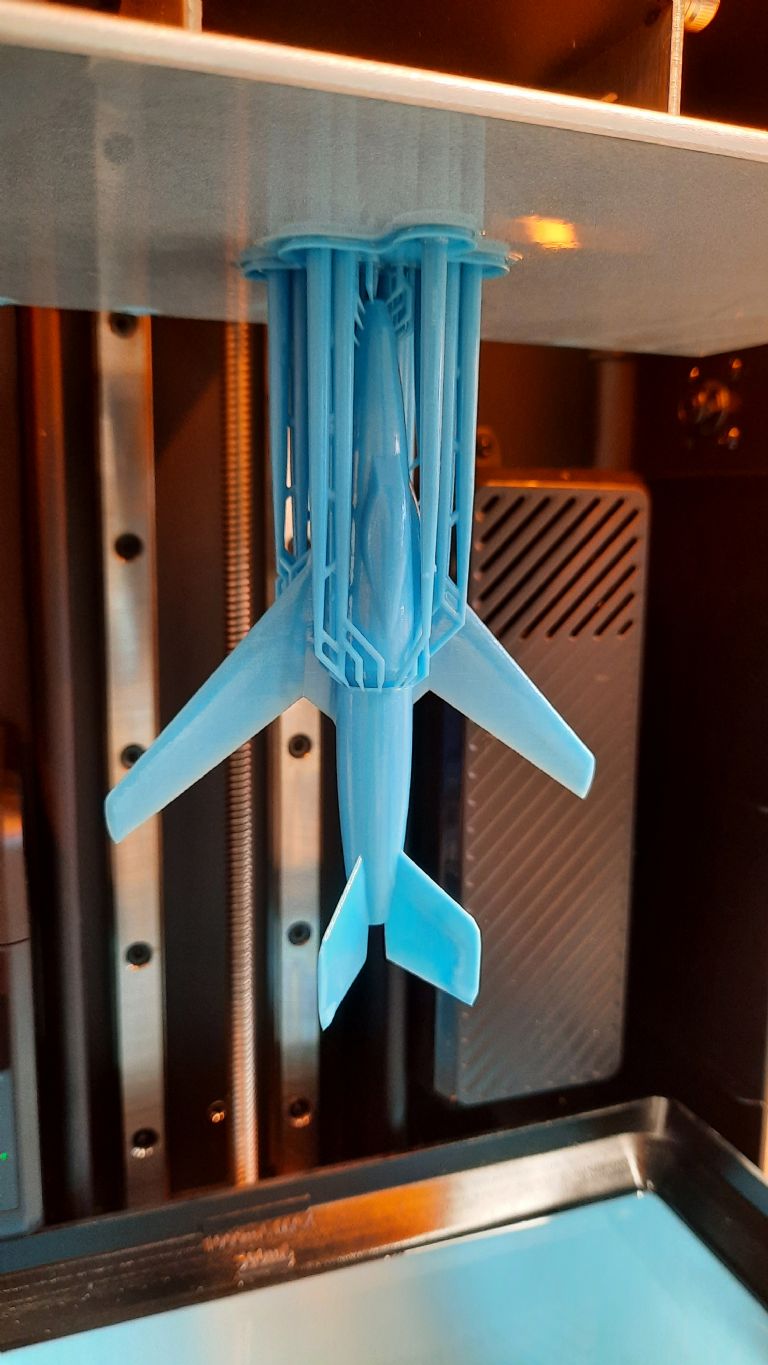

I mentioned a test of the same print on the Halot-Mage Pro and the Halot One-Pro, this was a 1:72 version of my P110 model, deliberately oriented to give a tall print. Speedwise, the Dynax mode was the difference between ‘this evening’ and ‘tomorrow morning’. To my eyes there wasn’t any noticeable difference in quality despite the print only taking a quarter of the time. What I would like to see is a somewhat tougher fast resin, as the Creality Fast Resin supplied for the test is in the ‘crisp but brittle’ category better suited to models than working parts – you might spot a small chip I broke off the wing when using forceps to handle the model.

Conclusion

The Halot-Mage Pro is an advanced resin printer with a large build volume and capable of very delicate work, even when running in the high speed Dynax mode. This alone will make it attractive to many people, but the addition of several ease-of use features such as the flip up cover, ventilation system and smart pump greatly add to its ease of use. I’m looking forward to further testing its capabilities.

You can view the Halot-Mage Pro online at https://bit.ly/3NjiqcE